Without semiconductors, chips cannot be made; but with semiconductors, high-end chips may not be made - this is the "smile curve" of the industrial chain.

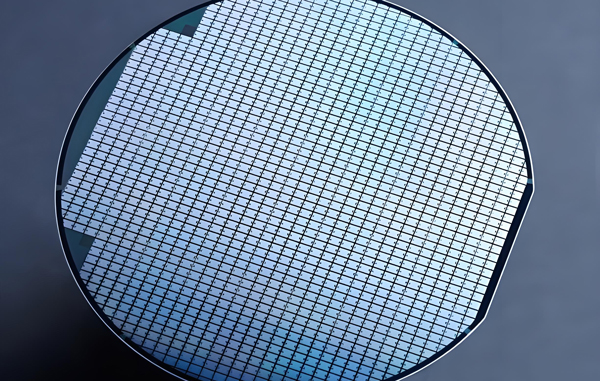

Semiconductor: Playing "purity magic"

The silicon wafer used to make chips must have a purity of 99.9999999% (99), which is equivalent to only 1 drop of impurity allowed in a swimming pool water. It took SMIC 12 years to reduce the defect rate of the 28nm wafer from 3/10000 to 1/10000.

A popular metaphor: semiconductor purification is like "sifting out a perfect grain of sand from the desert", which tests the "patience" of materials scientists.

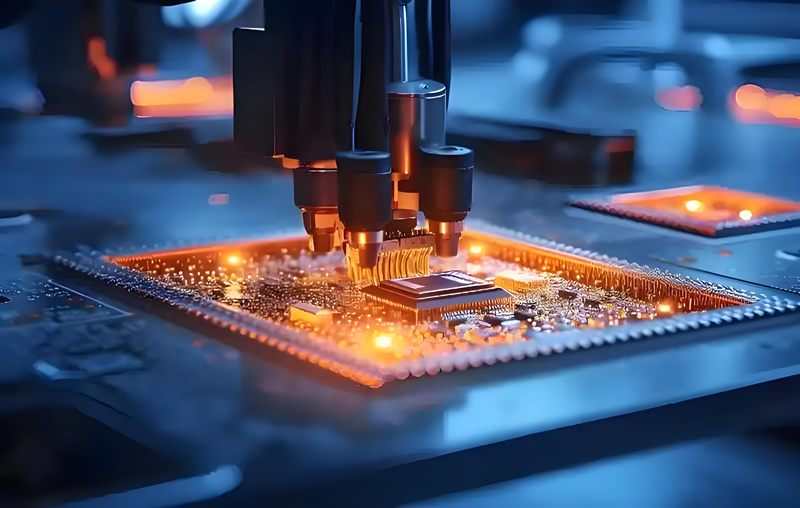

Chip: It is a pair of "nano engraving"

Chip manufacturing requires etching billions of transistors on a fingernail-sized wafer (with a 7nm process, transistors are smaller than viruses). TSMC's EUV lithography machine has the error of 0.1nm per exposure (equivalent to one thousandth of the hair).

A popular metaphor: Making a chip is like "carving "The Art of War" on a grain of rice", which tests the "precision" of the engineer.

Semiconductor materials: In addition to making chips, they are also used in LED lamps (gallium nitride), solar panels (polysilicon), sensors (silicon germanium), etc., and are the "vitamins" of modern industry. Your home smart speakers, car tire pressure monitoring, and even the temperature control modules of the refrigerator are inseparable from semiconductor materials.

Chip products: divided into CPU (computer brain), GPU (graphics card core), memory chip (mobile phone memory), etc. Each category has clear technical barriers. For example, Nvidia's H100 chip has a computing power equivalent to 200,000 ordinary computers, which are specifically used for AI training; while Huawei's Kirin chip has gained a foothold in the mobile phone SoC field by relying on its own architecture.

The "bottleneck" link of semiconductors

The "ecological barrier" of chips

x86 architecture: Intel and AMD monopolize PC chips and rely on Windows systems to form the "Wintel Alliance", making it difficult for new players to enter;

ARM architecture: Apple and Huawei use ARM to design mobile phone chips, but the ARMv9 architecture has begun to add "security backdoor", forcing China to develop RISC-V open source architecture;

EDA tools: 90% of the world's chip designs rely on the EDA software of Cadence and Synopsys in the United States. SMIC was forced to delay mass production of 14nm due to tool supply cuts.

Upstream: semiconductor materials (silicon wafers, photoresist), equipment (lithography machines, ion implanters) - typical enterprises: TSMC (equipment buyers), SMIC (wafer manufacturing);

Zhongyou: chip design (Huawei HiSilicon, Qualcomm), manufacturing (TSMC, Samsung), packaging and testing (Changdian Technology, Sun and Moonlight) - Typical case: Apple designed the A16 chip, handed over to TSMC for manufacturing, and then packaged by Sun and Moonlight;

Downstream: Terminal applications (mobile phones, computers, cars) - Typical data: The global chip market size in 2024 is US$595 billion, of which 19% of Chinese manufacturers account for, but the self-sufficiency rate of high-end chips (below 14nm) is less than 5%.

"Chinese chips are not good, so semiconductors are also lagging behind"

wrong! China is indeed behind semiconductor materials (silicon wafers) and equipment (lithography machines), but it has entered the first echelon in the field of chip design - Huawei Kirin 9000S and Cambrian Siyuan 590 are both high-end chips designed independently, but are restricted by manufacturing processes.

"The smaller the chip, the better, and the higher the semiconductor purity, the better"

wrong! 28nm chips are more durable in the automotive electronics and industrial control fields (thermal resistance is 3 times better than 7nm); semiconductor purity is not an unlimited pursuit, and power semiconductors (such as IGBTs) need to deliberately "dopants" to adjust their conductivity.

"Semiconductor industry = chip industry"

wrong! Semiconductors are a larger industry category, including the entire chain of materials, equipment, design, manufacturing, packaging and testing; chips are just the "fist products" of the semiconductor industry, just like the relationship between the "auto industry" and "engine".

Semiconductors solve the problem of "whether there is or not" is the "foundation" of manufacturing;

Chips solve the problem of "good or not" and are the "command heights" of the technological war.

If China wants to break through the dilemma of "lack of cores and souls", it must not only make up for shortcomings in semiconductor materials and equipment, but also build strengths in chip design and architecture. After all, only when both "flour" and "bread" can we truly grasp the right to speak in the industrial chain.