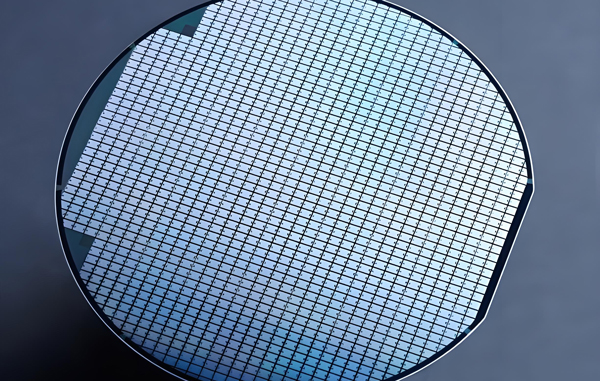

Lianke Semiconductor has taken an important step in the field of liquid phase silicon carbide crystal growth furnaces, and has successfully completed the on-site acceptance work of customers recently. This not only proves their continued innovation in the growth technology of silicon carbide single crystals, but also marks that their technological accumulation in this field has reached a new level. With deep experience in the growth of straight-pull single crystals and silicon carbide single crystals, Lianke Semiconductor has successfully launched a liquid-phase crystal growth furnace that can flexibly adapt to the needs of 6 to 8-inch single crystal growth. These crystal growth furnaces not only support a variety of heating methods, but also significantly improve production efficiency and optimize crystal quality.

The advantages of liquid phase technology are gradually being recognized by the industry, especially in the growth of P-type silicon carbide substrates, which show unique advantages. It can grow high-quality silicon carbide wafers with low dislocation density, and greatly improve production yield and reduce production costs. Today, liquid phase crystal growth technology has become an important direction for the development of the silicon carbide industry. In order to promote the further development and application of this technology, equipment manufacturers and substrate manufacturers need to work closely together to welcome the prosperity of the silicon carbide industry.

Recently, Shanxi Zhongdian Ke New Energy Technology Co., Ltd. has made significant progress in the purification technology of ultra-high-purity graphite powder, successfully overcome the core problems in the purification process of graphite powder, and has made the purity of the product reach the domestic leading level. The company used its own purification equipment to finely purify graphite powder with a raw ash of 700ppm, and finally obtained a purity of up to 5N (99995%), and the content of all metal elements was lower than the detection lower limit. This technological breakthrough not only marks a solid step in Shanxi Zhongpin Technology's graphite powder purification field, but also lays a solid foundation for the company's development in the fields of new energy and high-end materials. Looking ahead, the company will continue to increase its investment in core technology research and development to further enhance its technical strength and market competitiveness. This important progress not only demonstrates the company's continuous efforts in technological innovation, but also provides the industry with a production solution for higher purity graphite powder, further promoting the industrialization of ultra-high purity materials.

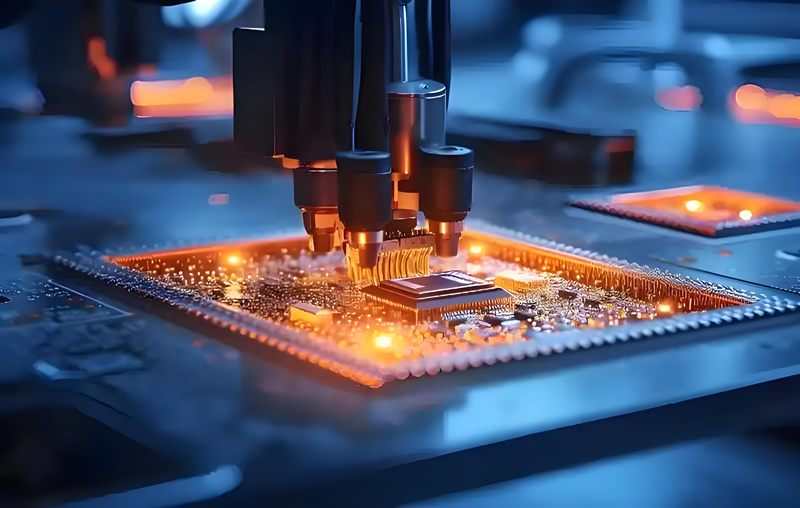

Jiangsu General Semiconductor Co., Ltd. recently successfully delivered its independently developed 8-inch silicon carbide ingot laser stripping equipment, and has been successfully put into production. The achievement of this important milestone marks a new and major breakthrough in SiC ingot stripping technology in China.

Compared with the traditional wire cutting process, general semiconductor laser stripping technology not only significantly reduces product losses, but also greatly reduces production costs. The price of this equipment is only one-third of similar products abroad, making it the first innovative equipment in China to realize this technology. Since its research and development began in 2023, Jiangsu General Semiconductor has successfully launched the first 8-inch fully automatic SiC ingot laser stripping production line in China.

With this disruptive technology, Jiangsu General Motors can accurately peel off ultra-thin silicon carbide wafers with a thickness of only 130 microns from the ingot, which not only reduces production costs, but also significantly improves production efficiency. With the continuous upgrade of automation technology, the speed and yield rate of equipment have also been greatly improved, and fully automatic sharding of 6-inch and 8-inch crystal ingots has been fully realized.

At present, with the gradual introduction of equipment to the market, Jiangsu General Motors has made an appointment until next year. It is expected that after all production lines are put into operation, the annual production of silicon carbide substrates will reach 20,000 pieces. The company plans to further accelerate the industrialization process of equipment to expand market share and promote technological innovation and cost reduction in the silicon carbide industry chain.

Wolfspeed, a leading silicon carbide (SiC) chip manufacturer, recently announced that its president and CEO Gregg Lowe has resigned. The change occurred when the company faced a complex situation where the company faced a decline in demand for electric vehicles and a reduction in orders in the industrial and energy terminal markets, reflecting the company's strategic adjustments in response to market pressure.

In the announcement, Wolfspeed stressed that the CEO replacement is intended to drive the company's long-term value growth, especially in the context of the booming global semiconductor industry, the demand for silicon carbide materials continues to be strong. However, Wolfspeed also faces many serious challenges. The company's board of directors has decided to remove Gregg Lowe from its CEO position immediately and set out to find new leaders to lead the company in seizing market opportunities.

In addition, Wolfspeed has also announced a series of restructuring and layoff plans. The company plans to close a 150mm plant and is expected to incur $7.4 billion in restructuring costs. The layoffs will involve about 1,000 employees, aiming to address the current market dilemma by reducing costs. Meanwhile, Wolfspeed has decided to shelve plans to build a factory in Ensdorf, Germany to meet the weak demand in the European electric vehicle market.

Despite the possible $2.4 billion in funding, Wolfspeed still faces many difficulties in the transformation to pure 200mm silicon carbide wafers and equipment manufacturing under the Chip Act. In the future, how Wolfspeed overcomes these challenges will become the focus of industry attention.

Geqi Compound Semiconductor, an emerging silicon carbide (SiC) manufacturer, recently held a grand inauguration ceremony of the new factory in Zhongli District, Taoyuan, Taiwan.

The total investment of the factory is as high as NT$600 million (equivalent to approximately RMB 3.3 billion), and is expected to be fully put into production in the fourth quarter of 2024. After the new factory is completed, the monthly production capacity will reach 5,000 pieces of 6-inch silicon carbide substrates, and 20 8-inch crystal furnaces and 100 6-inch crystal furnaces are planned to be added by the end of 2024, thereby significantly increasing the overall production capacity. This significant increase in production capacity indicates that Geqi's layout in the SiC market will be further strengthened.

At the inauguration ceremony, Geqi also signed a cooperation agreement with the Chinese Academy of Sciences in Taiwan and Mitsubishi, Japan. According to the agreement, the three parties will jointly work on the research and development of high-frequency communication silicon carbide components and plan to enter the market of key components required by 5G/B5G communication infrastructure. This cooperation not only deepens the technological exchanges between Taiwan and Japan, but will also further expand the demand for SiC products in the Japanese market, especially in the fields of consumer and automotive applications.

Through this cooperation, Mitsubishi will provide Japanese customers with 6-inch and 8-inch crystal ingots, wafers and epitaxial materials, while Geqi will rely on the resource advantages of Taiwan to provide Japanese customers with corresponding SiC material support. This series of measures indicates that Geqi's market position in the SiC field will be further consolidated and improved.

According to Jiangfeng Electronics' third quarter report for 2024, the company showed strong growth momentum.

Operating income reached 2.5 billion yuan, an increase of 77% over the same period last year; net profit was 8.7 billion yuan, an increase of 51% over the same period last year. In the third quarter, the company achieved operating income of 9.8 billion yuan and net profit of 2.6 billion yuan, with year-on-year growth rates of 48% and 213% respectively.

The report also revealed that Jiangfeng Electronics has made important progress in the strategic layout of third-generation semiconductor materials. Its controlling subsidiary, Jingfeng Xinchi, has owned a number of patents on silicon carbide epitaxial structures and preparation methods, and recently released 6 to 8-inch silicon carbide epitaxial sheets, marking the company's technical strength in the field of silicon carbide. At present, the construction of the production line is progressing smoothly and has initially achieved production capacity, providing strong support for the company's market expansion.

In addition, Jiangfeng Tongxin, a subsidiary of Jiangfeng Electronics, has also made important breakthroughs in the production of copper clad ceramic substrates. Since its production starts, the company has achieved large-scale expansion in just 8 months, with the number of production lines increasing from 2 to 17. The monthly production capacity of DBC copper-clad ceramic substrate has increased from 10,000 pieces to 150,000 pieces. It is expected that by the end of 2024, the annual output will reach 500,000 pieces, exceeding the original target. This series of achievements demonstrates Jiangfeng Electronics' technical strength and market potential in the field of materials.

The research team at Xiamen University has made significant progress in silicon carbide (SiC) wafer cutting technology, and they have proposed an innovative dual-laser induced microcrack generation and expansion technology.

This technology successfully achieved non-contact, low-damage sections of 500μm thick SiC samples, while ensuring that the surface roughness after the slice is controlled below 200nm. This technological breakthrough not only provides a solid theoretical basis for the growth and interconnection of microcracks of SiC wafers, but also plays a key role in improving the processing accuracy and application performance of SiC wafers.

During the specific implementation process, researchers used nanosecond lasers to finely scan SiC materials. The laser pulse duration is 25 nanoseconds, the wavelength is 1064nm, the repetition frequency is as high as 10kHz, and the spot size is about 10μm. First, the high-energy density laser is focused inside the SiC material, causing the generation of multiple microcracks, thereby reducing the bonding intensity of SiC and enhancing the absorption of laser energy. Subsequently, a low-energy density laser beam scans the surface of the material, further promoting the expansion and connection of microcracks, and achieving efficient and accurate wafer slicing.

The successful development of this technology indicates that the manufacturing process of silicon carbide materials will be more efficient and cost-effective, and the yield rate will be significantly improved. This is of great significance for the wide application of silicon carbide in new energy, 5G communications, electric vehicles and

other fields.

Tianyue Xianjin recently launched the industry's first 300mm silicon carbide substrate. This industry milestone progress marks the official entry of silicon carbide materials into the era of super-large sizes.

With its excellent performance, this 300mm substrate not only refreshed the industry standard, but also won wide praise and heated discussions from customers and industry insiders at the press conference. With the rapid development of industries such as new energy vehicles, photovoltaic energy storage and 5G communications, the demand for silicon carbide-based devices has shown explosive growth. The launch of 300mm substrate will significantly increase chip production while reducing production costs, laying a solid foundation for the widespread application of silicon carbide materials.

Tianyue Advanced's innovative measures not only further enrich its product series, meet the diverse needs of customers, but also demonstrate the company's firm determination and continuous investment in technological innovation and product upgrades. This move will undoubtedly inject new vitality into the future development of the silicon carbide material industry and lead the industry to a more brilliant future.