The following is the optimized typed text, which improves readability through grading titles, segments and lists, while retaining all original information:

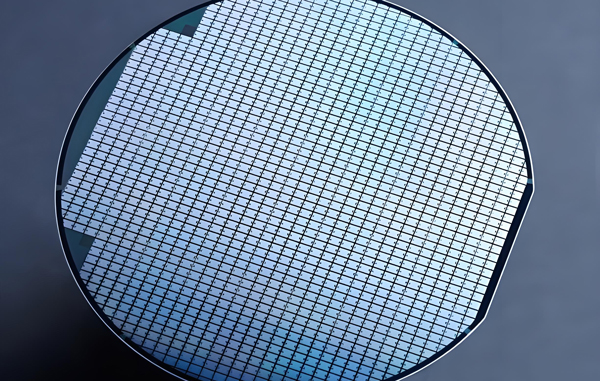

Chip manufacturing materials: the cornerstone of electronic engineering

Chip manufacturing materials are a crucial part of the field of electronic engineering. They are the basis for chips and directly affect the performance and reliability of chips. This article will elaborate on chip manufacturing materials from four aspects:

1. Semiconductor materials

Semiconductors are one of the most commonly used basic components in modern electronic devices, and their material selection determines the core performance of the chip:

Silicon (Si):

Widely used in large-scale integrated circuit manufacturing, due to its low cost, mature process and high stability;

Conductivity can be regulated through doping processes (such as phosphorus and boron).

Gallium arsenide (GaAs):

Excellent performance in high-frequency devices (such as 5G communication modules) and optoelectronic devices (such as lasers);

The electron mobility is much higher than silicon, but the cost is higher.

New semiconductor materials:

Silicon carbide (SiC): High voltage and high temperature resistance, suitable for electric vehicle power modules;

Gallium nitride (GaN): High frequency and high efficiency characteristics, promoting innovation in 5G base stations and fast charging technology.

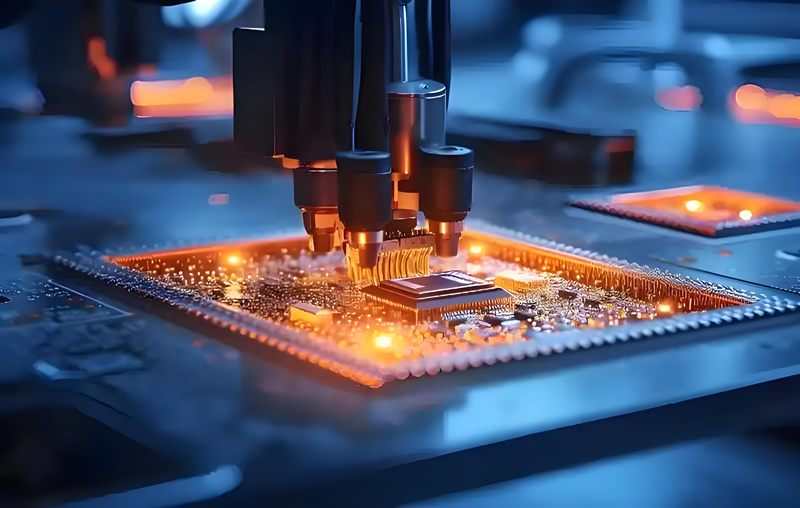

2. Metal materials

Metal materials are responsible for the interconnection and current transmission of internal components of the chip. Common material characteristics are as follows:

Aluminum (Al):

Early mainstream interconnect materials, low cost and simple process;

High resistivity limits high frequency performance.

Copper (Cu):

The resistivity is about 40% lower than that of aluminum, which significantly reduces signal delay and power consumption;

The etching process and diffusion problems need to be solved, and gradually replaced aluminum has become the mainstream.

Gold (Au):

Used for high reliability bonding wires, it has strong corrosion resistance but is expensive.

3. Insulator material

Insulator materials are used to isolate different components and prevent signal crosstalk. The main types include:

Silica (SiO?):

Classic gate dielectric material, excellent insulation performance and compatible with silicon process;

The dielectric constant is low, limiting the device to further shrinkage.

Silicon nitride (Si?N?):

High mechanical strength, better heat resistance and diffusivity than SiO?;

Used for passivation layer or high k dielectric transition layer.

4. Packaging materials

The packaging material protects the chip and enables connection to external circuits. Key requirements include:

Epoxy resin:

Mainstream packaging substrate materials, low cost and good processability;

Thermal conductivity needs to be improved through fillers (such as silica).

Thermoplastics:

Such as liquid crystal polymer (LCP), suitable for high-frequency packaging;

High temperature resistance and low hygroscopicity, but high cost.

Summary

Chip manufacturing materials are the core elements that determine chip performance and reliability:

Semiconductor materials provide a functional basis, and metal materials achieve efficient interconnection,

The insulator material ensures electrical isolation, and the packaging material completes final protection and connection.

With breakthroughs in materials science (such as two-dimensional materials and superconducting materials), chip manufacturing is moving towards a new era of higher performance and lower power consumption. In the future, interdisciplinary materials innovation will become the key path to continue Moore's Law.