-

Ultra-clean, high-purity wet electronic chemicalsSpecializes in the production of semiconductors (TR, IC), crystalline silicon solar energy (solar PV), FPD Special electronic ultra-clean and high-purity reagents for flat panel display (TFT-LCD, CF, TP, OLED, PDP, etc.) and LED, silicon wafer, lithium battery, optical magnetism and other processesLearn moreUltra-clean, high-purity wet electronic chemicals

Ultra-clean, high-purity wet electronic chemicalsSpecializes in the production of semiconductors (TR, IC), crystalline silicon solar energy (solar PV), FPD Special electronic ultra-clean and high-purity reagents for flat panel display (TFT-LCD, CF, TP, OLED, PDP, etc.) and LED, silicon wafer, lithium battery, optical magnetism and other processesLearn moreUltra-clean, high-purity wet electronic chemicals -

Silicone and environmentally friendly surfactant series productsSpecializes in the production of semiconductors (TR, IC), crystalline silicon solar energy (solar PV), FPD Special electronic ultra-clean and high-purity reagents for flat panel display (TFT-LCD, CF, TP, OLED, PDP, etc.) and LED, silicon wafer, lithium battery, optical magnetism and other processesLearn moreSilicone and environmentally friendly surfactant series products

Silicone and environmentally friendly surfactant series productsSpecializes in the production of semiconductors (TR, IC), crystalline silicon solar energy (solar PV), FPD Special electronic ultra-clean and high-purity reagents for flat panel display (TFT-LCD, CF, TP, OLED, PDP, etc.) and LED, silicon wafer, lithium battery, optical magnetism and other processesLearn moreSilicone and environmentally friendly surfactant series products -

Waste acid recycling projectSpecializes in the production of semiconductors (TR, IC), crystalline silicon solar energy (solar PV), FPD Special electronic ultra-clean and high-purity reagents for flat panel display (TFT-LCD, CF, TP, OLED, PDP, etc.) and LED, silicon wafer, lithium battery, optical magnetism and other processesLearn moreWaste acid recycling project

Waste acid recycling projectSpecializes in the production of semiconductors (TR, IC), crystalline silicon solar energy (solar PV), FPD Special electronic ultra-clean and high-purity reagents for flat panel display (TFT-LCD, CF, TP, OLED, PDP, etc.) and LED, silicon wafer, lithium battery, optical magnetism and other processesLearn moreWaste acid recycling project -

otherSpecializes in the production of semiconductors (TR, IC), crystalline silicon solar energy (solar PV), FPD Special electronic ultra-clean and high-purity reagents for flat panel display (TFT-LCD, CF, TP, OLED, PDP, etc.) and LED, silicon wafer, lithium battery, optical magnetism and other processesLearn more其他

otherSpecializes in the production of semiconductors (TR, IC), crystalline silicon solar energy (solar PV), FPD Special electronic ultra-clean and high-purity reagents for flat panel display (TFT-LCD, CF, TP, OLED, PDP, etc.) and LED, silicon wafer, lithium battery, optical magnetism and other processesLearn more其他

Jiangsu Jingjiu Microelectronics Materials Co., Ltd. was established in 2016 and is headquartered in Jintan New Materials Industrial Park (provincial chemical park). The company is a key enterprise specializing in the production of high-end ultra-clean and high-purity wet electronic chemicals in China. Its main business covers R&D, production and sales, and serves high-tech industries such as semiconductors, display panels, and new energy.

The company's workshop has a construction area of ??nearly 30,000 square meters, with a level 1,000 purification production area of ??5,000 square meters and a level 100 purification production area of ??2,000 square meters, and is equipped with a complete set of ultra-clean production equipment and testing instruments that meet the SEMI G4 level standards.

The company has formed more than 60 electronic-grade chemical product systems, mainly including: general-purpose wet electronic chemicals, such as hydrogen peroxide, sulfuric acid, hydrochloric acid, nitric acid, phosphoric acid, hydrofluoric acid, methanol, isopropanol, acetone, N-methylpyrrolidone, etc.; functional chemicals, such as silicon etching liquid BOE, silicone desiccant solution, aluminum/copper/silver/tiger/titanium/chromium metal etching liquid, developer, stripping liquid, negative glue rinse liquid, edge glue cleaning agent, etc.; photoresist and supporting reagents, such as KrF glue, ArF glue, bottom anti-reflective coating (BARC), top anti-reflective coating (TARC), etc.

The company's service areas include: semiconductor wafer process (IC, TR), display panel (OLED, TFT-LCD, CF, TP) new energy (crystalline silicon solar energy, energy storage smart controller), and others (LED, lithium battery, PCB, optical and magnetic) and so on. It supports customized formula and OEM services, and the product packaging ranges from 0.5L to 1000L tons of barrels and ISO TANK tank trucks to meet different customer needs.

The company's team has more than 20 years of industry experience and has established cooperative relationships with nearly 200 customers and has worked closely with many scientific research institutes and well-known companies. The enterprise has complete innovation qualifications and has been rated as a national high-tech enterprise, a national science and technology-based small and medium-sized enterprise, and a specialized and specialized small and medium-sized enterprise. It has a postdoctoral innovation practice base. The company's testing center adopts full-process quality monitoring to ensure "stable quality and timely delivery". The production system adopts automated control and precise formula ratios to ensure high purity and consistency.

The company adheres to the development concept of "quality first, reputation first, and customer first", and is committed to becoming an industry-leading electronic chemical company, promoting the import substitution of domestic high-end ultra-clean chemicals to create an industrial benchmark for continuous innovation and green development.

-

30000 m 2R&D and Production Base

-

8632 wRegistered capital

-

50 year +Industry experience

-

10 +Honorary Qualifications

-

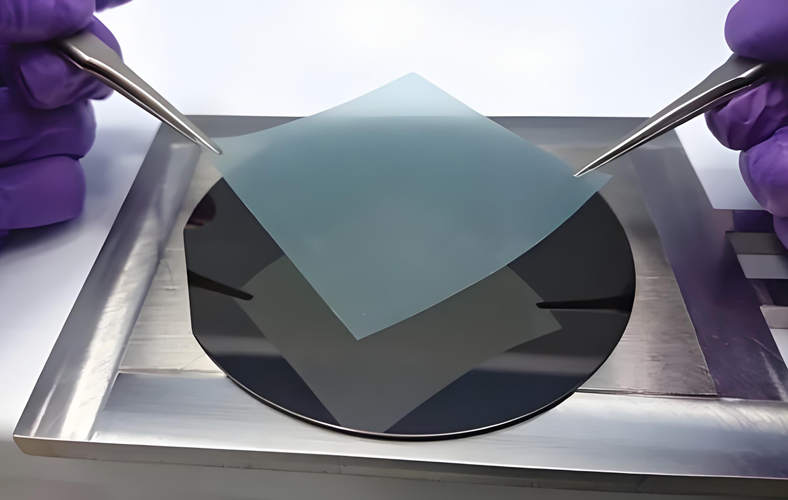

Semiconductor film process: nano-scale coats made by chipsThe semiconductor film process is an indispensable basic link in chip manufacturing. Its essence is to accurately deposit or grow nano-scale films on the wafer surface, giving the chip conductive, insulating or protective functions.2025-03-26

Semiconductor film process: nano-scale coats made by chipsThe semiconductor film process is an indispensable basic link in chip manufacturing. Its essence is to accurately deposit or grow nano-scale films on the wafer surface, giving the chip conductive, insulating or protective functions.2025-03-26 -

Although the chip is small, it is an extremely large and complex project to make it.The chip production process enlarges the chip by 100,000 times. These things smaller than viruses are transistors, and hundreds of billions of transistors form a chip. How did such a small thing be made? First,2025-03-26

Although the chip is small, it is an extremely large and complex project to make it.The chip production process enlarges the chip by 100,000 times. These things smaller than viruses are transistors, and hundreds of billions of transistors form a chip. How did such a small thing be made? First,2025-03-26 -

-

Mail

jsjingjiu@jingjiu-mc.com -

Tel

0519-82612578 -

Official Account

-

Top